Plastic Injection Moulding

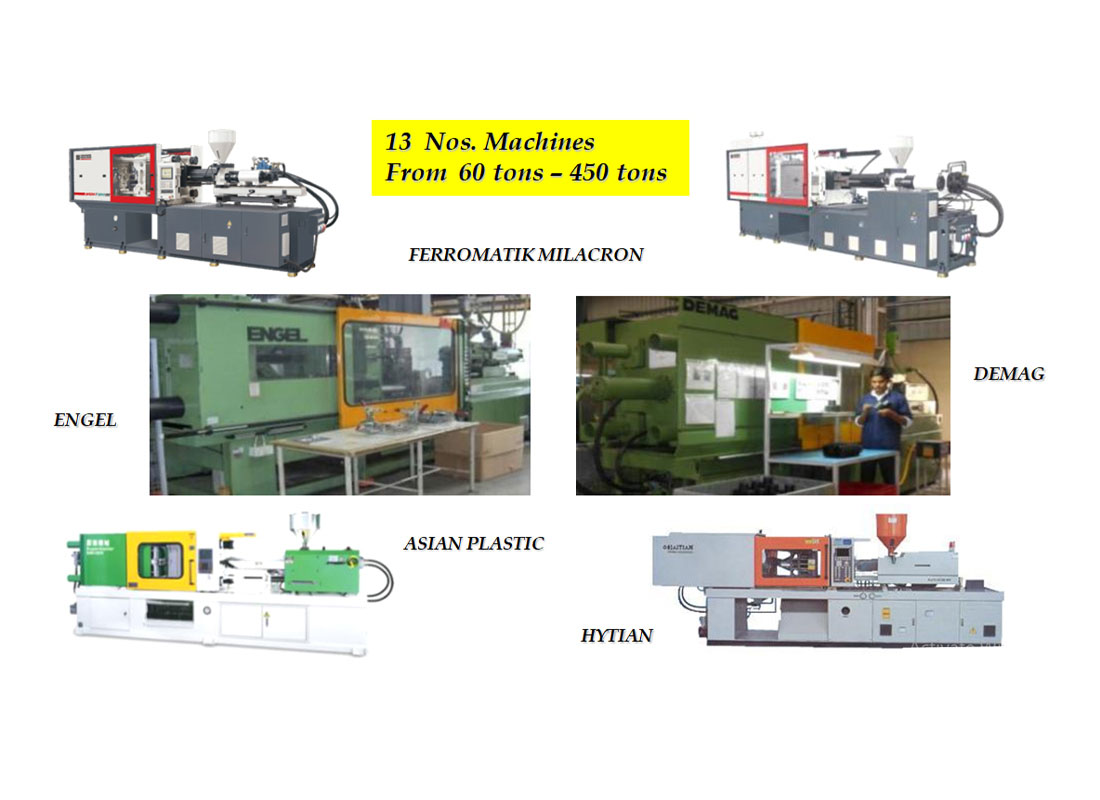

Range of 50 to 450 Ton Thermoplastic injection moulding micro-processor based, Good quality machine’s suitable process for any engineering material.. We manufacturing components from 1 grams to 1000 grams, In almost 40+ engineering polymers, Mainly doing for automotive & Engineering application.